|

型號(hào) |

Model |

RZS(一體機(jī)) |

|

理論速度 |

Theoretical speed |

0.19秒/點(diǎn) ?0.19sec/pcs |

|

插入方向 |

Insertion angle |

標(biāo)準(zhǔn):-90°~+90°,360°可選,增量為1° ?Standard: -90 °~+90 °, 360 ° optional, in increments of 1 ° |

|

元件種類 |

Components style |

電容器、晶體管、三極管、LED燈、按鍵開關(guān)、電阻、連接器、彈簧 、電位器、保險(xiǎn)絲座、熔斷絲等立式編帶封裝料,紙帶孔距12.7/15.0mm Vertical tape packaging materials such as capacitors, transistors, LED lights, key switches, resistors, connectors, springs, potentiometers, fuse holders, fuse links, etc., with hole spacing of 12.7mm/15.0mm |

|

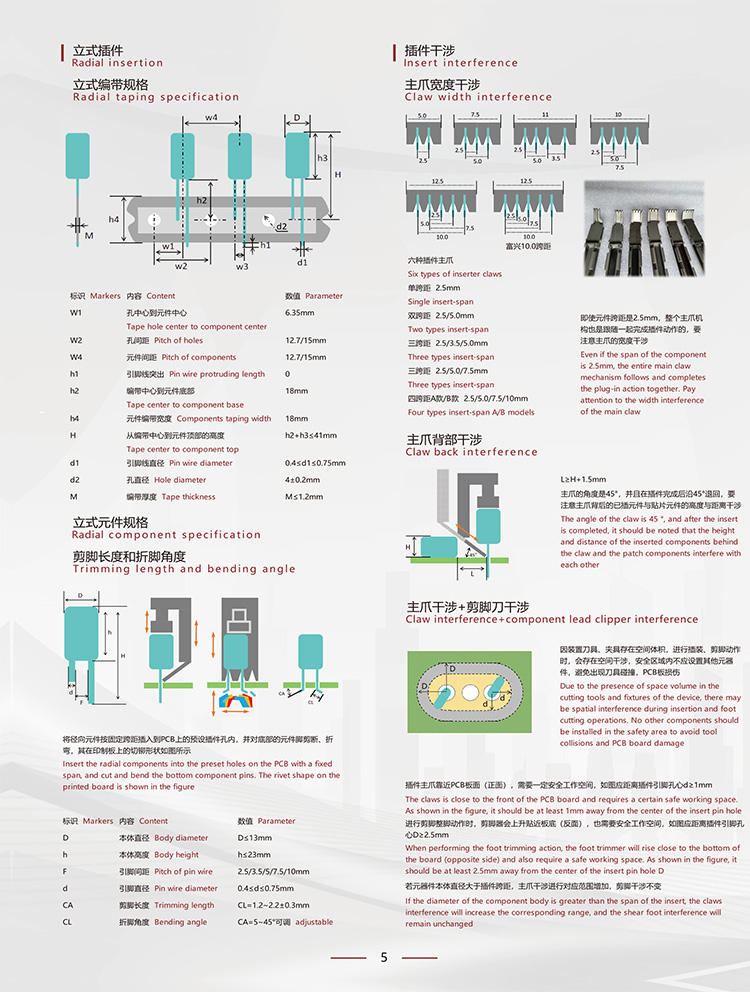

元件規(guī)格 |

Components specifications |

最大高度為23mm,最大直徑為13mm(可定制) Maximum height is 23mm, maximum diameter is 13mm (customizable) |

|

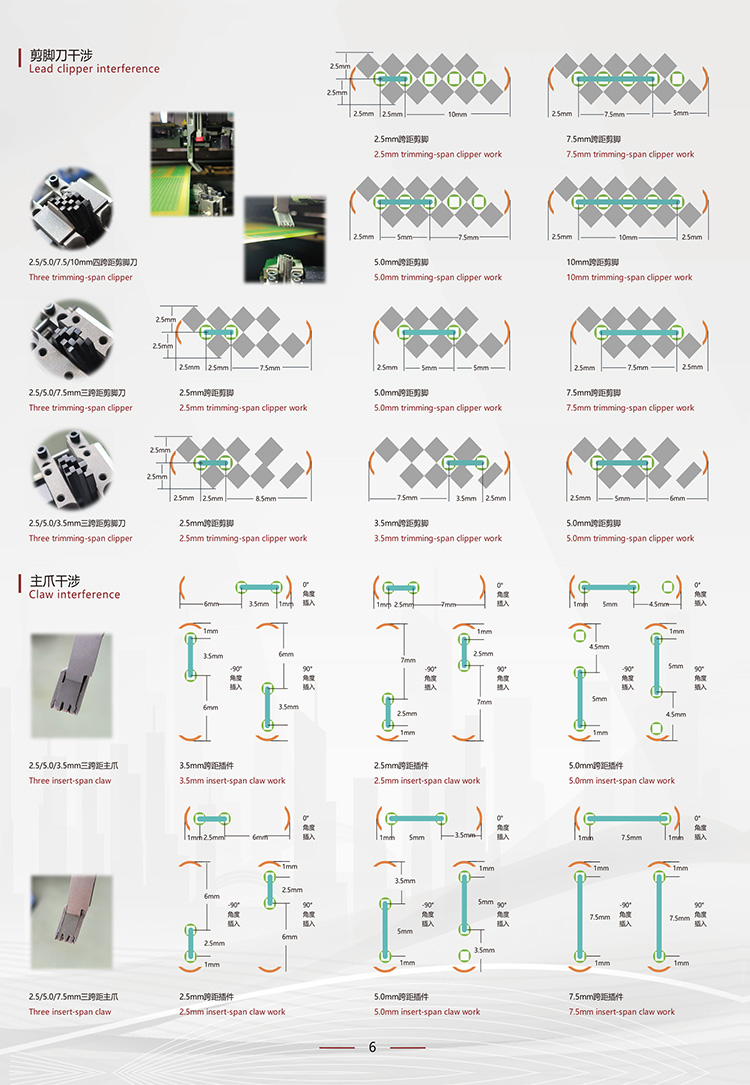

引線跨距 |

Lead span |

雙間距2.5/ 3.5/5.0/7.5/10.0mm(可選配) Double spacing 2.5/ 5.0/7.5/10.0mm(optional) |

|

元件引線剪角長(zhǎng)度 |

Component lead trimming length |

1.2~2.2mm(可調(diào))??adjustable |

|

元件引線彎角角度 |

Component lead bending angle |

5-45°(可調(diào))??adjustable |

|

基板尺寸 |

Substrate size |

50*50mm~400*280mm |

|

基板厚度 |

Substrate thickness |

0.79~2.36mm (標(biāo)準(zhǔn):1.6mm) 0.79-2.36mm(Standard: 1.6mm) |

|

線路板輸送方式 |

Circuit board transportation mode |

全自動(dòng):左→右(標(biāo)準(zhǔn))或右→左(選配) ?Fully automatic: left right (standard) or right left (optional) |

|

基板傳送高度 |

Substrate conveying height |

900±20mm |

|

基板傳送速度 |

Substrate transfer speed |

3 sec/pcs |

|

PCB上下元件可通過(guò)高度 |

Components pass through height on PCB |

上23mm/下8mm ?23mm above/8mm below |

|

驅(qū)動(dòng)系統(tǒng) |

Driving system |

AC伺服,AC馬達(dá) ?AC servo, AC motors |

|

孔位校正方式 |

Hole position offset method |

CCD影像視覺(jué)系統(tǒng),MARK點(diǎn)視覺(jué)校正 CCD image vision system, MARK point visual correction |

|

底座驅(qū)動(dòng)方式 |

Base drive mode |

電磁閥+精密氣缸 ?Imported solenoid valve+precision cylinder |

|

CTA送料方式 |

CTA feeding method |

電磁閥+精密氣缸 ?Imported solenoid valve+precision cylinder |

|

編程方式 |

Programming method |

離線/在線(快速掃描編程功能) Offline/Online (Quick scan programming function) |

|

數(shù)據(jù)輸入方式 |

Data input methods |

USB接口輸入(EXCEL文檔格式) ?USB input (EXCEL document-format) |

|

不良PCB板識(shí)別 |

Identification of defective |

具有不良PCB板自動(dòng)識(shí)別功能? Automatic recognition function for defective PCB boards |

|

防漏件系統(tǒng) |

Leak proof component system |

自動(dòng)識(shí)別補(bǔ)料 ?Automatic identification of replenishment materials |

|

控制系統(tǒng) |

Control system |

Windows操作系統(tǒng)中英文界面、視窗平臺(tái)、液晶顯示 ?? Windows operating system, Chinese&English interface, platform, LCD display |

|

MES系統(tǒng) |

MES system |

無(wú) ?Without this feature |

|

使用電源/功率 |

Power requirement |

220V,AC(單相)50/60HZ ,約1.5KW |

|

使用氣壓/用氣量 |

Use air pressure/gas |

0.6MPA/0.3立方米/分鐘 ?0.6 mpa/ 0.3 m3/ min |

|

主機(jī)尺寸 |

Main machine size |

L1760mm×W1780mm×H1785mm(10站)10 feeders |

|

L2518mm×W1782mm×H1785mm(20站)20 feeders |

||

|

料站尺寸 |

Feeder station size |

無(wú)分體料站 ?Without split feeder station |

|

機(jī)器重量 |

Machine weight |

含12站位約1500KG ?Approximately 1500kg(with 12 feeders) |