|

型號(hào) |

Model |

JVA(跳線機(jī)) |

|

理論速度 |

Theoretical speed |

0.16秒/點(diǎn) ?0.16sec/pcs |

|

插入方向 |

Insertion angle |

平行0°,90°,180°,270° ??Parallel |

|

元件種類 |

Components style |

跳線?jumper |

|

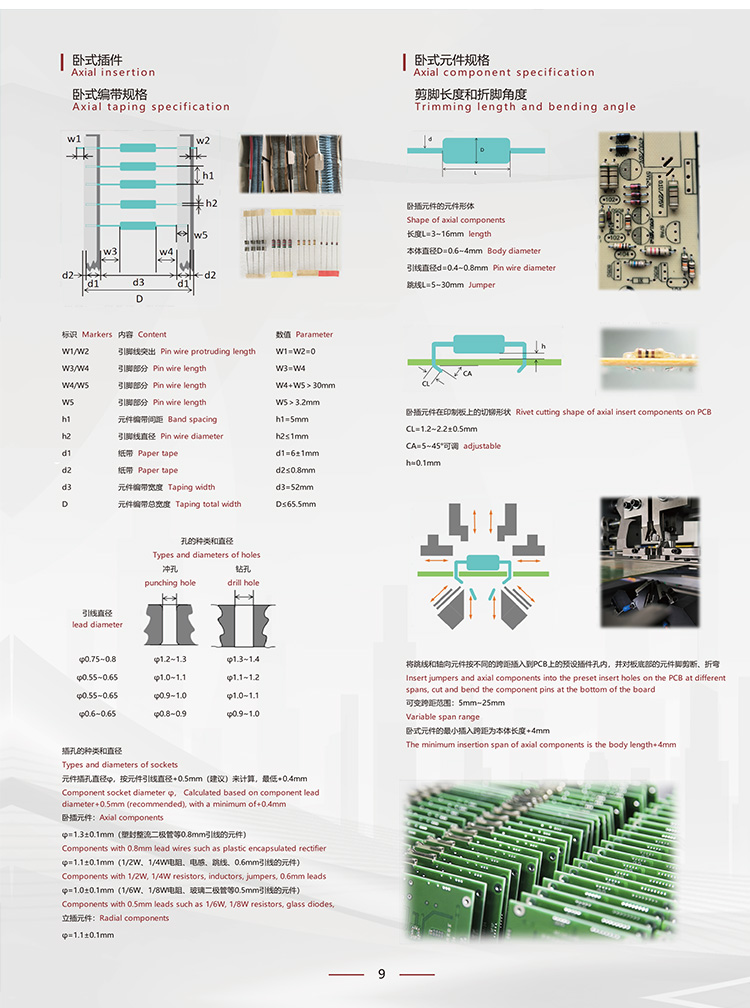

元件規(guī)格 |

Components specifications |

引線直徑:0.4~0.8mm ?Lead diameter |

|

引線跨距 |

Lead span |

專插入跳線5~30mm Specially inserted jumper |

|

元件引線剪角長(zhǎng)度 |

Component lead trimming length |

1.2~2.2mm(可調(diào)) ?Adjustable |

|

元件引線彎角角度 |

Component lead bending angle |

5-45°(可調(diào)) ?Adjustable |

|

基板尺寸 |

Substrate size |

50*50mm~330*280mm |

|

基板厚度 |

Substrate thickness |

0.79~2.36mm (標(biāo)準(zhǔn):1.6mm) 0.79-2.36mm(Standard: 1.6mm) |

|

線路板輸送方式 |

Circuit board transportation mode |

全自動(dòng):左→右(標(biāo)準(zhǔn))或右→左(選配)?Fully automatic: left right (standard) or right left (optional) |

|

基板傳送高度 |

Substrate conveying height |

900±20mm |

|

基板傳送速度 |

Substrate transfer speed |

3 sec/pcs |

|

PCB上下元件可通過(guò)高度 |

Components pass through height on PCB |

上12mm/下8mm ?12mm above/8mm below |

|

驅(qū)動(dòng)系統(tǒng) |

Driving system |

AC伺服,AC馬達(dá) ?AC servo, AC motors |

|

孔位校正方式 |

Hole position offset method |

CCD影像視覺(jué)系統(tǒng),多點(diǎn)MARK視覺(jué)校正 ?CCD Image visual systems, multi-point MARK visual correction |

|

底座驅(qū)動(dòng)方式 |

Base drive mode |

伺服電機(jī) ?Servo motor |

|

供料器方式 |

Base drive mode |

跳線站 ?Jumper station |

|

編程方式 |

Programming method |

離線/在線(快速掃描編程功能) ?Offline/Online (Quick scan programming function) |

|

數(shù)據(jù)輸入方式 |

Data input methods |

USB接口輸入(EXCEL文檔格式) ?USB input (EXCEL document-format) |

|

Badmarks識(shí)別 |

Identification of defective PCB board |

具有不良PCB板自動(dòng)識(shí)別功能 ?Automatic recognition function for defective PCB boards |

|

控制系統(tǒng) |

Control system |

Windows操作系統(tǒng)中英文界面、視窗平臺(tái)、液晶顯示 ? |

|

MES系統(tǒng) |

MES system |

無(wú) ?Without this feature |

|

使用電源/功率 |

Power requirement |

220V,AC(單相)50/60HZ ,1.5KW ??Single phase |

|

使用氣壓/用氣量 |

Use air pressure/gas |

0.6MPA/0.3立方米/分鐘 ?0.6 mpa / 0.3 m3/ min |

|

設(shè)備尺寸 |

Main machine size |

L1800mm×W1500mm×H1810mm |

|

機(jī)器重量 |

Machine weight |

約1300KG ?Approximately 1300kg |